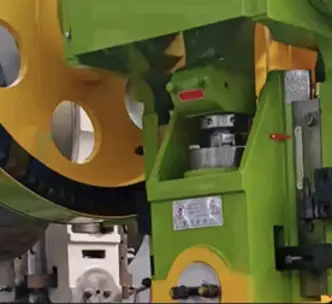

sheet metal punch press machine

60 ton punch press for sale

punch press machine price:3800 dollars

● Characteristic

This of sheet metal punch press machine for sale is equipped with a manual oil lubrication device. The manual oil pump is easy to operate and helps reduce friction and mechanical resistance in the punch press.

The punch press machine design is very precise, and punch press machine parts (such as crankshaft, screw rods, electrical appliances and ball joints etc) are checked by our quality inspection department to ensure the punch quality and service life.

Clients can choose punch press machine guarding such as grating protection and protective isolation net for their punch press machine.

By changing different dies, the punch press machine metal can produce different metal products and have different usages, it can be hole punch press machine, punch press cutting machine and punch press machine for metal forming.

● Parameter of 60 ton punch press

| Model | J23-63t |

| Punch press machine capacity | 630 |

| Nominal Stroke(mm) | 100 |

| SPM (times/min) | 60 |

| Die Height Adjustment(mm) | 80 |

| Between Slide Center and Frame(mm) | 240 |

| Bolster(mm) | 450x710 |

| Blanking hole diameter(mm) | 170 |

| Main Motor Power(kw) | 5.5 |

| Outline Dimension(mm) | 1600x1150x2480 |

| Weight(kg) | 3100 |

● transportation and After Sales Service

FYCHIS Maquinaria is one of the punch press machine manufacturers in China. FYCHIS Maquinaria dedicates to industrial automation system development and production, production and sales of sheet metal punch press machine etc. We can offer punch press machine for sale with punching capacity from 10 ton to 200 ton. Our advanced technology and perfect management system can ensure the high quality of punch power press machine. Our technical team can provide our clients with professional techinical service. In addition, we have professional freight forwarder with long-term cooperation to offer our clients good transportation service with low cost.

there are many punch press machine manufacturers in India, we still send many punch press machines to punch press machine supplier in Mumbai. Because our punch press machine for sale has good quality and the punch press machine price is low, we also offer good service. Our mass production speed is much faster than punch press machine manufacturers in India. Besides India, we send our die punch press machine to Deutsch, Indonesia, Peru, vietnam, Mexico, Colombia and Chile etc.

● Sheet metal punch press machine use

Our punch press machines are mainly for sheet metal. Our sheet metal punch press machine for sale can be used for blanking, punching and forming etc. and it’s widely used in various industries, for exaple, electric socket, horizontal shaft engine parts, cupboards, dishes, computer cases, household appliances, furniture, vehicles (cars, motorcycles, bicycles, tricyles and hardware parts etc.

● FREQENT ASKED QUESTIONS

What are safety precautions for punch press machine?

Due to the characteristics of high speed and high pressure of the punch press machines, the use of punch press machines for punching and forming must comply with certain safety regulations. the punch press machine operator must be trained and familiar with operating procedures.

1. Use the safety protection and control device of the punch press machines correctly and do not disassemble it.

2. Before starting up the punch press machine check whether the main fastening screws are loose, whether the dies are cracked, whether the operating mechanism, automatic stop device, clutch and brake works well, whether the lubrication system is blocked or lacks lubrication oil.

3. When installing the dies to the punch press machine, the slider must be lowered to the bottom dead center, the shut height must be correct, and the eccentric load must be avoided as much as possible; the dies must be fastened firmly and checked by pressure test.

4. It is strictly forbidden to use hands to put the work piece on the lower die. Small work pieces must be placed and taken with special tools (tweezers or feeding mechanism).

5. If it is found that the punch press machine is running abnormally or there is abnormal sound (such as batter sound), the feeding should be stopped immediately and check the punch press machine to eliminate the problem.

6. After starting the mechanical punch press machine, the operator should stand up properly, keep hands and head at a certain distance from the mechanical punch press machine. And always pay attention to the movement of the slider. the operator of the mechanical punch press machine must not be distracted in the operation of the mechanical punch press machine.

What are the reasons and solutions for the vibration of the punch press machine?

The reasons for vibration in a mechanical punch press and their corresponding solutions are as follows:

1, Imbalance: Imbalance of components such as the flywheel or crankshaft can cause vibration during operation. The solution is to adjust or rebalance the relevant punch press machine parts.

2, Misalignment: Improper alignment of parts such as the die, punch, or guide rod can lead to vibration. The solution is to ensure proper alignment of these components and tighten them securely.

3, Wear or damage: Excessive wear or damage to punch press machine parts like bearings, gears, or belts can result in vibration as they may not function properly. The solution is to regularly inspect and replace worn or faulty parts.

4, Insufficient machine rigidity: Inadequate rigidity of the machine can cause vibration. The solution may involve increasing the machine's rigidity through reinforcing the structure or using a more stable base.

5, Excessive punching load: If the workpiece is too large or the impact load applied during the punching process is too high, it can lead to vibration. The solution is to adjust the working parameters of the punch press appropriately to operate within the recommended load range.

6, Cooling system issues: Malfunctioning or insufficient cooling systems can result in increased temperature, leading to vibration. The solution is to ensure the cooling system is operating properly and perform maintenance and cleaning as required.

7, Control system issues: Faulty control systems or improper operation by untrained personnel can cause vibration. The solution is to ensure the control system is functioning correctly and provide training to operators on proper operation.

To address vibration issues in a sheet metal punch press machine, implement the aforementioned solutions based on the specific situation. Additionally, regular maintenance and inspections should be conducted to ensure the stability and proper functioning of the punch press.