Punching Press Machine for Sale

J23-10T punching press machine for sale

punching press machine price:600 dollars

ejecucion de prueba de maquina troqueladora metal 10 toneladas

● Characteristic of power press punching machine

1. The small press punching machine of 10 ton has cast structure and good vibration resistance.

2. The crankshaft of the punching press machine for sale is placed horizontally and the open external gear is convenient for maintenance.

3.The punching press machine for sale is equipped with collapse overload protection device. If the slider is overloaded, the fuse will collapse, protecting the punching press machine for sale and dies form damage.

4.With manual switch operation button and foot pedal, the sheet metal punching machine for sale can be operated continuously.

5.This press punching machine can do automatic production with automatic feeding mechanism.

● Parameter of punching press machine

| Nominal Force(ton) | 10 |

| Nominal Stroke(mm) | 50 |

| SPM (Times/min) | 140 |

| Die Height Adjustment(mm) | 40mm |

| Bolster(mm) | 350×220mm |

| Between Slide Center and Frame(mm) | 120mm |

| Blanking hole diameter(mm) | 95mm |

| Outline Dimension(mm) | 800x600x1500mm |

| Main Motor Power | 1.1KW |

| Net Weight(kgs) | 300kg |

● Transportation and after sales service

Chongqing Popular Motor is a reputable manufacturer of punching press machines based in China. With our advanced product development center and efficient management system, we ensure the production of high-quality power press punching machines. Our dedicated loading team guarantees prompt and timely product loading. Partnering with a reliable freight forwarding agent company, we offer professional and competitive international freight forwarding services at a low shipping cost.

We take pride in providing excellent pre-sales service, assisting you in selecting the mechanical punching machine best suited for your production needs. Our technical team is highly skilled and committed to delivering professional and timely support. Additionally, we offer a comprehensive range of press punching machine parts to meet your requirements. Our punching machines for sale (10 ton punch press to 200 ton punch press) have won unanimous praise from domestic and international customers due to its stable performance.

Choose Chongqing Popular Motor as your trusted partner for all your mechanical punching machine needs. We are committed to delivering top-notch products, reliable services, and customer satisfaction.

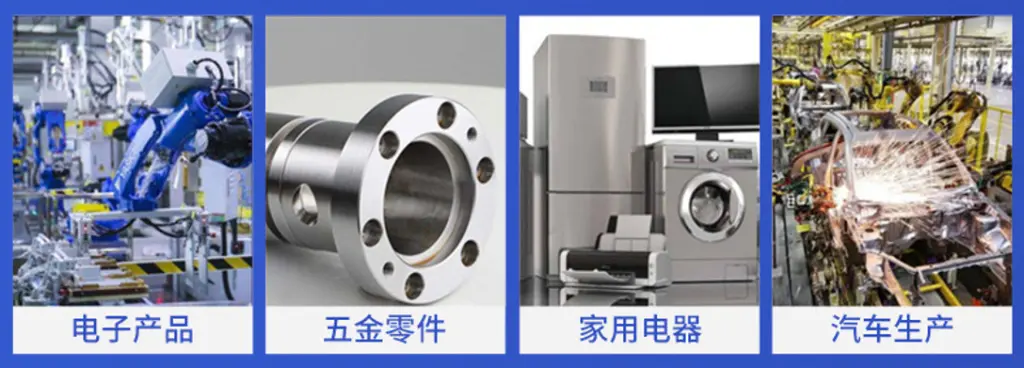

● Punching press machine use

The press punching machine is a metal processing machine that uses pressure to deform metal and make it shape that is needed.

The mechanical press punching machine includes hydraulic press punching machine, pneumatic press punching machine, mechanical press punching machine and cnc press punching machine etc. Pneumatic press punching machine and mechanical press punching machine are usually used for hardware products processing while the cnc press punching machine is mainly used in die-cutting of non-metallic products.

This 10 ton punch press is a small press punching machine for sheet metal processing, cutting, stamping, blanking, and shallow deep drawing of sheet metal. The power press punching machine can be used for metal products such as metal sheets of electrical plugs, computer cases. We have also punch power press machine 15 ton, 40 ton punch press, 60 ton punch press, 80 ton punch press, for the production of motorized wheelbarrow and parts of construction machine such as mini concrete pump.

● Questions and answers

What are the problems that need to be paid attention to when using a power press punching machine?

(1)Before starting, check whether the protective device of the sheet metal punching machine for sale is complete and whether the flywheel is running smoothly. Whether there is any protection on the upper part and both sides of the pedal device, whether the operation is reliable and flexible. Remove objects that obstruct the operation of the power press machine punching machine from the workplace.

(2)Inspect the sheet metal before starting the punching press machine. Ensure that there is no foreign matter or cracking on the surface of the sheet metal to prevent foreign matter from popping up during processing the sheet matal.

(3)When more than two people operate the same power press punching machine, one person should be designated to press the start button. Install protective cover for transmission parts exposed to the outside of the punching press machine for sale. It is forbidden to operate the punching press machine for sale or do test run of the punching press machine for sale with the protective cover removed. When the power press machine punching machine is working, any part of the operator’s body is strictly prohibited from entering the range of the dies, and there should be special tools for feeding and retrieving workpiece.

(4)Concentrate when operating the punching press machine. It is strictly forbidden to extend hands or tools into the danger zone. If the power press punching machine is found to be running abnormally or there is abnormal noises, stop feeding and check the power press punching machine. Every time when one workpiece is done, the hand must leave the button or the foot must leave the pedal to prevent misoperation.

(5)The blanking force of the punching press machine for sale must be confirmed, and overload operation is strictly prohibited.

(6)When installing and disassembling the press punching machine dies, the power supply of the press punching machine must be cut off first. The slider should stop at the bottom dead center for the installation and disassembly of the power press machine punching machine die. The press punching machine must be fastened firmly and checked by trial run. Check the condition of the punching press machine die regularly, adjust in time if there is looseness or slippage.

(7)It is forbidden to punch more than one workpiece at the same time. The second feeding can only be carried out after the previous punch or residual material has been cleared.

(8)The power press punching machine and dies should be cleaned after finishing work.