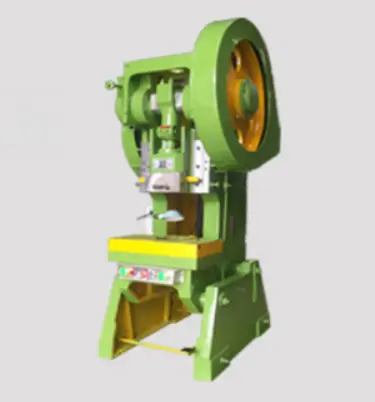

Mechanical Punch Press

Punching Capacity: 16 Ton Mechanical punching machine price: 1400 dollars

● Characteristic of mechanical punch press machine

This punching machine for mechanical engineering is equipped with two slider balancers to ensure that the punching machine for mechanical engineering maintains a balanced operation.

The highly sensitive punch press mechanical clutch and brake, duplex electromagnet and overload protection device can ensure the accuracy and safety of the operation and stop of the mechanical punch press.

The adjustment precision of the slider adjustment mechanism can reach 0.1MM.

The crankshaft, gears, gear shafts and other friction parts of the mechanical punching machine are all hardened through heat treatment before grinding. These mechanical punch press parts have extremely high wear resistance and stable performance.

This 15 ton punch press can work with other automatic feeding mechanism to do automatic production so that can lower the cost and improve efficiency.

● Parameter of mechanical punching machine

| Product Name | 15 ton punch press |

| Die Height Adjustment(mm) | 40mm |

| Nominal Force(ton) | 16t |

| Nominal Stroke(mm) | 60mm |

| SPM (Times/min) | 130/min |

| Blanking hole diameter(mm) | 160mm |

| Main Motor Power | 2.2KW |

| Bolster(mm)) | 290*460mm |

| Between Slide Center and Frame(mm) | 180mm |

| Outline Dimension(mm) | 1020*800*1900mm |

| Weight(kg) | 900 |

● Mechanical Punch Press Parts

● Transportation and after sales service

FYCHIS Maquinaria is funded in 2004. It’s one of mechanical punch press manufacturers in China. Our mechanical punch press for sale has good quality and we sell our mechanical punch press for sale to many countries, Mexico, Peru, Indonesia and Vietnam etc. We have profesional shipping agent company to provide clients with optimal transportation plan and low shipping freight. We can offer you professional pre-sales service to help you buy a mechanical punching machine that befits your production. Our technical team do after sales service and offer you suggestion in the production. Also, we can offer our clients all mechanical punch press parts:punch press mechanical clutch, flywheel, mechanical punch press die etc. Contact us if you need more information ahout mechanical punch press for sale and mechanical punching machine price.

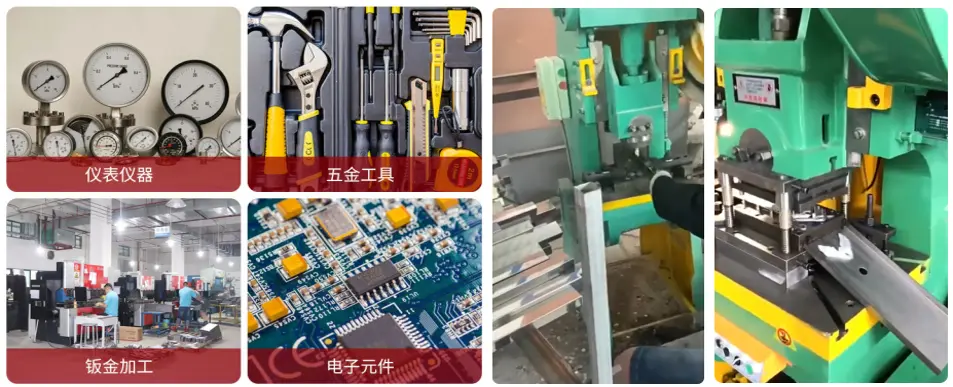

● Mechanical punch press use

A mechanical punching machine is a metal processing equippment that uses pressure to shape the sheet metal. To finish the mechanical punching process the mechanical punch press die is needed. The mechanical punching process is very simple: put the sheet metal on the lower mechanical punch press die with tool and step on the foot switch, the upper mechanical punch press die hits the sheet metal and the mechanical punching work is done. Compared with traditional mechanical processing, mechanical punching process saves materials and energy and can make product effects that cannot be achieved by mechanical processing, so it has become more and more widely used.

This mechanical punching machine has the mechanical punching capacity of 16 tons. Can be used to produce electronic components, instruments, cold cut metal saw parts, toys, decoration, hardware tools, horizontal engines, automobiles and machinery etc.

● FREQENT ASKED QUESTIONS

Define mechanical punch press

The mechanical punch press is the kind of machine that takes advantage of high pressure to deform the workpiece. Before the use of the mechanical punch press, these operations were all done by hand - inefficient and laborious. The design principle of mechanical punch press machine is to convert circular motion into linear motion: the flywheel is driven by the main motor, and the gear, crankshaft (or eccentric gear) and connecting rod are driven by the clutch to achieve the linear motion of the slider. The movement from the main motor to the connecting rod is circular. The mechanical punch press for sale presses the material to plastically deform to obtain the required shape and accuracy. Therefore, it is necessary to use dies (the upper die and the lower die), place the material between the dies, and the mechanical punch press for sale applies pressure to deform it. With the emergence of mechanical punch press, metal stamping becomes easier, more accurate and more efficient. Generally, mechanical punch press is used for sheet metal stamping.

What are types of mechanical punch press?

There are a variety of classification standards for mechanical punch press machine. As we have mentioned before, the mechanical punch press machine can be divided into crank mechanical punch press, eccentric gear mechanical punch press10, knuckle mechanical punch press, friction mechanical punch press, screwmechanical punch press, rack mechanical punch press, link mechanical punch press and cam mechanical punch press according to the drive mechanism of the mechanical punch press nachine.

The mechanical punch press also can be divided into fixed table mechanical punch press and inclinable mechanical punch press according to the structural characteristics of the work table.

The fixed table mechanical punch press has good rigidity and anti vibration stability, and can be made into larger tonnage.

Inclinable mechanical punch press, whose body can be tilted back at a certain angle (generally 25 ° or 30 °), so that the workpiece (or waste) can be discharged from the rear of the mechanical punch press because of its own weight.

Deep throat mechanical punch press is another kind of mechanical punch press that the distance from the center of the mold handle hole to the rear wall panel is larger than that of a ordinary mechanical punch press. It can be 300mm, 500mm, 800mm and even 1250mm. And can do customized production of deep throat mechanical punch press according to actual production needs.